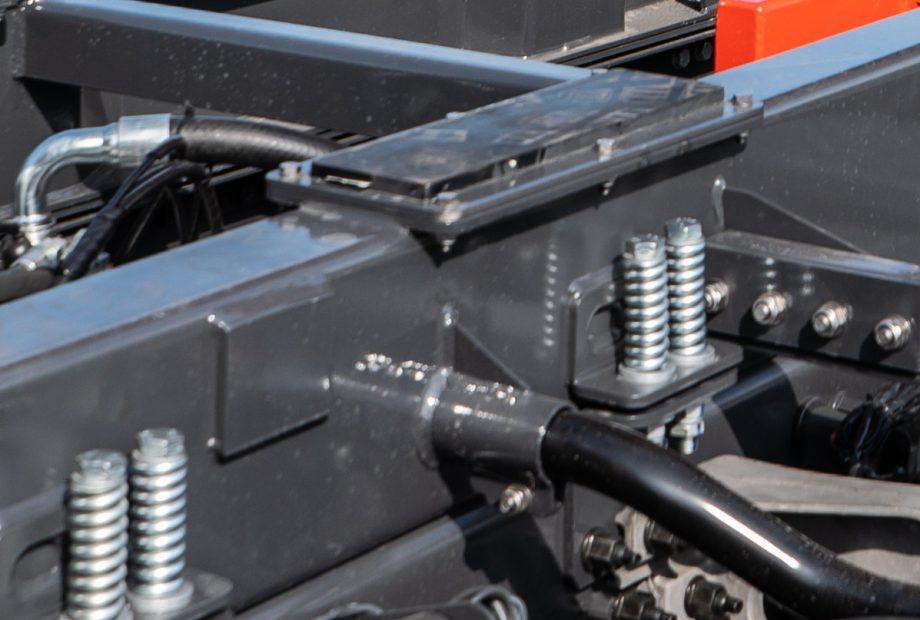

VS-MONT S1GT : developed for maximum efficiency of transporting asphalt mixtures. Thanks to its attractive design, the S1GT design is a real eye-catching device. S1GT is based on a modern welded composite construction with a high-quality thermal insulation system of the superstructure with a coverage area of up to 92%. As a result, it combines maximum payload with high strength. Our one-sided superstructures S1GT are designed for the most demanding customers in the field of transport of asphalt and other mixtures. They are optimized for wear and insensitive to cracks. Thanks to the combination with a stabilizer and the correct use of the hydraulic system, our S1GT rear tipper is particularly stable with the lowest possible placement in the tipper subframe. The S1GT thermal superstructure can be combined with various temperature measurements (eg temperature indicator on the superstructure, form of document printing with a given temperature in the driver’s cab, etc.). The large tipping angle in conjunction with the full cone shape of the tipper makes it easy to pour asphalt mixtures into the paver. The low center of gravity guarantees good stability on the road and the best driving characteristics thanks to these features, the S1GT is the ideal tool for all transport needs in the sector.